Pakmar offers „green” packaging materials

Pakmar sp. z o.o is present on the Polish market of packaging materials since 1990. Our mis-sion is to present the newest packaging trends to our customers and hence we take into consideration every major stake occurring in today’s packaging market in order to adapt our current products to packaging needs or elaborate totally new materials. Consequently, we have been working on the development of solutions, which take into consideration the environmental issues. That being said, we would like to present three of our newly elaborated material technologies.

BIOPAP-paper laminate/PLA: entirely made out of renewable resources

Nowadays, more than 99% of plastics, including the ones used for packaging production, are manufactured with fossil resources, mainly petroleum and natural gas. Despite the fact that this production mode is the most optimal from an economical point of view, it is neither sustainable, nor respectful towards our already harmed environment.

Taking into consideration that with the current stage of technology we are incapable of inte-grally replacing traditional materials, demands are being put forward to reduce the packaging waste and increase the usage of renewable resources in the manufacture of packaging materials, provided it is technically possible. The paper laminate/PLA is our response to these postulates. An initial research indicates that the vast majority of packaging customers value a natural look of the laminate, especially ones whose outer layer is made of “raw” Kraft or bleached papers, as in the photo below. This construction is satisfactory both from an aesthetic point of view and in terms of overprint quality. The PLA is a sealable layer in the laminate.

The BIOPAP laminate as a lidding film for paper pulp trays

The considerations concerning the possible application of The BIOPAP laminate are being directed towards lidding foil of trays composed of PLA or other natural resources such as wood pulp, bran or sugar cane, where the BIOPAP would give an easy-to-open seal (peel), thus in every scenario the user of the packaging would dispose of a product, which is 100% renewable. Another possible application of the paper /PLA laminates are stand up pouches which are 100% compostable.

BIOLIDS-laminate cellulose foil/PLA : 100% compostable

The component foils are certified with the DIN Certo certificate of compostability responding to the expectations of the packaging market , especially in food industry, since this sector highly values alternative solutions fulfilling the demands of the Gospodarka o Obiegu Zamkniętym ( the circular economy system).

The newly developed laminates BIOLIDS 1915 and BIOLIDS 1930 are characterised by a high rigidity, (modulus of elasticity > 2000 MPa) and have as well good optical properties (5,0% haze). These can be reverse and surface printed.

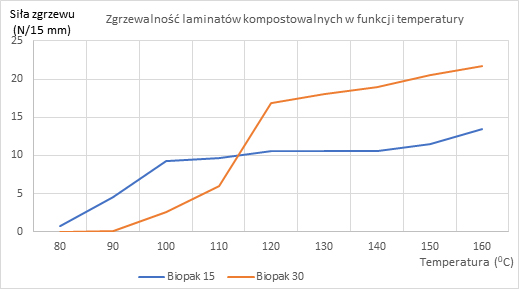

The sealability of the BIOLIDS laminates as a function of temperature

The BIOLIDS laminates, such as the previously mentioned BIOPAP, are characterised by an excellent sealability to trays made of PLA, which is illustrated on the graph above. In the case where the trays are produced using renewable material, the seal will be of the “peel” type.

The barrier of the laminates will be formed on a level similar to the used cellulose foil. For foils, it is 5 cm3 / m2 24h 24h, 0.1 MPa for oxygen and <1.0 g / m2 24h for steam under nor-mal conditions (230C and 50% above).

The BIOLIDS laminate, due to its stiffness, is mainly predisposed for the production of stand up and other types of pouches, as it is illustrated in the following photo. Nevertheless, it may also be used as a lidding film for trays, top film for FFS machines and for flow pack applications.

Multilayer polyethylene mono-material laminate

The laminate is made of two layers of PE with different function.

A special polyethylene foil is used as an external layer, characterised by a higher stiffness and thermal resistance. This foil plays the same role as PET, OPP foils, paper or aluminium foil in traditional laminates, which enable thermal application and drying without damaging the entire structure. The sealing layer is an LDPE foil or a composition that provides easy opening, based on polyolefins.

Multi-material structures , such as PET/PE or PA/PE will become problematic, since they will have to meet EU Directive requirement to become 70 % recyclable by 2030. Such a rate is not attainable using only rigid and semi-rigid packagings, Flexible packaging recycling will also be required, which in the case of multi-material structures requires the use of compatibil-izers, a solution that is not optimal from an economical point of view. Hence the proposal of a mono-material laminate seem to solve the problem.

The PE mono-material laminate does not provide the oxygen barrier, although it has an ex-cellent barrier against water vapour. For the 60mic / 60 mic 120mic laminate structure , the water vapour transmission will be less than 2 g / m2 24 h in tropical conditions, 380 C and

90% rh.

There exists a vast range of food products, for which low water vapour permeability is the only essential factor in the barrier of the packaging.

The PE mono-material laminate is suited for practically every form of packaging, ranging from bags of a different construction to flow pack applications.

The next step concerning the development of this type of material would be the elaboration of a metalized version of the foil.

Although, if such a product would be of interest in the future, it is possible to consider an introduction of a metallized laminate, which would create a barrier against oxygen as well as would give the PE laminate greater stiffness and thermal resistance, combined with the PE/EVOH/PE foil laminate. Currently, mono-matrerial laminates are available for testing, with thickness PE30 + PE50peel, as lids for trays and packages made of PE, PE60 + PE50 and PE60 / PE80 for packages made of PE lock type, as well as packaging for standing bags and with a string. If you are interested, we invite for testing.

Contact;

pakmar@pakmar.com.pl papier@pakmar.com.pl tel.22 8993225