PAKMAR invests in the production of food bags

PAKMAR Sp. z o.o. [Ltd.] has been present on the Polish market of packaging and raw materials since 1990.

Our aim is to present our customers with the latest developments in the field of packaging techniques. Based on our own experience as well as that of our customers and suppliers, we offer full service, from the selection of the packaging concept that is optimum for a given product to its adaptation to the technological needs of the customer. We strive to create and modify our market offer to meet the needs of the most demanding contractors. We choose innovative solutions with the highest added value for the customer.

Pakmar specializes in the supply of flexible and rigid barrier films for vacuum packaging and MAP for the food industry. Apart from the Polish market, which is our dominant market, we develop export activities in Belarus, Ukraine, Russia, Azerbaijan, Lithuania and Hungary.

In Poland, we deliver our products to over 500 customers, mainly in the food industry (meat, dairy, fish, poultry, fruit and vegetable, pharmaceutical) and printing industry (various films and materials for packaging and printing producers).

The implemented SAP computer system and ISO 22000 and BRC certificates allow us to meet the highest requirements of our customers in terms of quality and logistics of the delivery.

Our offer also includes PLA biodegradable and compostable films, which are dedicated to the production of packaging as well as for thermo-shrinkable labels and windows for packaging and envelopes.

As far as PLA biodegradable films are concerned, we cooperate and represent the world's leading manufacturer of biodegradable films from Plastic Suppliers - Sidaplax USA.

Pakmar is also a significant producer of vacuum packing bags and doypack bags. This direction of production development is currently strongly developed in the face of growing market demand. In order to meet these trends, Pakmar has invested in a modern production line.

What the EarthFirst PLA film is?

EarthFirst PLA is an environmentally friendly, biodegradable and compostable film produced by Plastic Suppliers. Production takes place using the extrusion technique, from biopolymers produced by Nature Works from biodegradable raw materials based on corn grains.

The film has been developed as an alternative to sources based on the petrochemical industry.

It has FDA certificates for contact with food as well as biodegradability and compostability certificates in accordance with the EN 13432 standard.

BAGS FROM PLA FILM

An important application of PLA film are bags for packing fresh and dried herbs and any loose products that do not require high barrier properties.

Advantages of EarthFirst PLA bags

- 100% compostable.

- Made using environmentally friendly production processes.

- They have high purity, transparency and high gloss.

- They are characterized by excellent susceptibility to processing and printability.

- There are no special requirements for packaging or storage.

- They are an excellent alternative to plastic bags.

- High temperature resistance.

- Compliance for natural printing (38 dyn without corona treatment).

- Good slip properties.

- Excellent resistance to fats and oils.

- Moisture can freely pass through the walls of the bags, which prevents the effect of fog.

Available types of bags

We strive to make sure that our EarthFirst PLA biodegradable film bags meet all your technological and visual requirements.

Currently available on request:

- Flat bags:

◦ Standard;

◦ With adhesive strip;

◦ On the wicket;

- Bags with envelope bottom.

- Bread-type bags.

- Bags for herbs in pots.

The offer is constantly being enlarged with new variants.

Knurled bags for vacuum packaging

Knurled film is a classic construction of polyamide and polyethylene film used for vacuum packaging. This film is distinguished by an embossing (grid) on one side of the bag, which enables packaging in a vacuum by most of the external equipment on the market.

Knurled film bags provide an excellent barrier to oxygen and water vapor, very high mechanical resistance and very good transparency. The bags are suitable for packing most food products on vacuum sealers.

They are commonly used in small food production plants as well as in gastronomy due to the possibility of packing on vacuum sealers (low investment cost below 150 dollars).

Variants of manufactured bags:

Flat bag with side and bottom welds for vacuum packaging of products - also available with printing and a side cut for easy opening.

- Dimensions:

◦ height - from 30 mm to 900 mm;

◦ width - from 30 mm to 650 mm;

- The minimum volume of that dimension is 5000 pcs.

- Standard available dimensions:

◦ 150x200 mm;

◦ 150x250 mm;

◦ 200x300 mm;

◦ 300x400 mm;

◦ packed in cardboard boxes or films of 50 pieces in each;

VACUUM SEALER

It is a chamberless machine for vacuum packing of food into knurled film bags. It is not possible to pack on this machine ordinary PA/PE bags without a knurl.

Vacuum packaging by removing the air from the packaging allows for long shelf life and freshness of the food.

The machine allows you to vacuum-pack into knurled bags with a maximum seal width of 280 mm.

Thanks to its compact size and ease of use, the sealer can be used both in small catering outlets and in households.

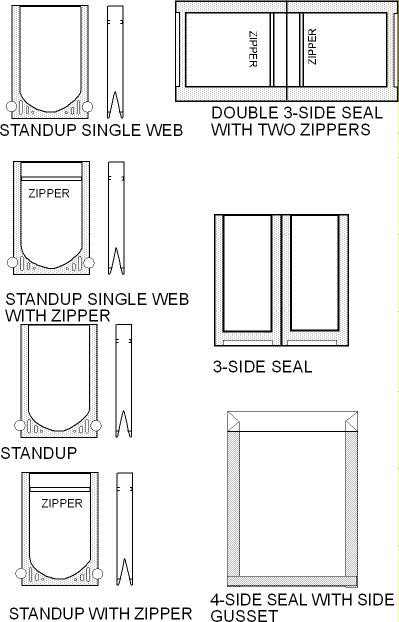

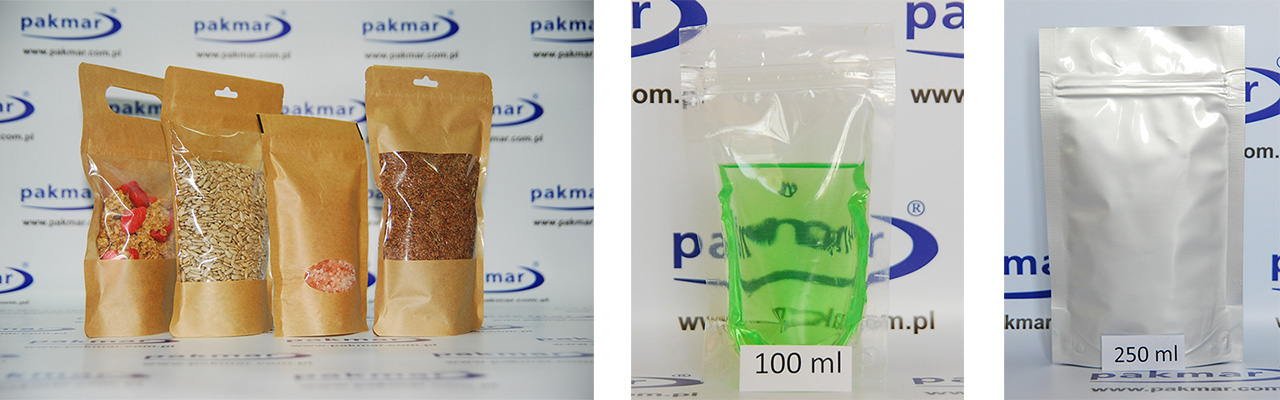

Standing sealing bags

Pakmar offers a very wide range of doypack bags and bags with side folds. A modern production line can produce bags with:

- 1 ribbon,

- Two types of materials

- Four types of materials (in case of bags with a side fold)

Bags made of PA/PE, OPA/PE, OPP/PE film

They are used for packing almost all food products, eg: bones, meat, poultry, cured meat, vegetables, fruits and goods that require plastic packaging that is durable and resistant to mechanical damage (tools, pens, etc.).

For packing fish and cured sliced meat we recommend clear bags with metallic foundation ( PET/PE) in gold. This packaging perfectly exposes the packaged goods and prolongs its life.

Bags made of duplex, triplex, quadruplex laminates (eg. PET/AL/PET/OPP, PET/AL/PE, OPP/PET/met/PE, paper/AL/PE, etc.)

They are used for packing aggressive products such as mushrooms, sauces, sauerkraut, pickled cucumbers, ketchup, mustard etc. in souse, sour; bulk products: coffee, tea, cocoa, jelly, pudding. The use of laminates, where one of the components is aluminum foil, results in the product packaged in such a bag having excellent barrier properties allowing to preserve the freshness and flavor of the product for a long time.

Variants of manufactured bags:

| Dimensions | Flat bag | Doypack bag | Sachet |

| Width A [mm] | 75 – 580 | 60 – 350 | 60 – 350 |

| Length H [mm] | 75 – 580 | 100 – 450 | 100 – 500 |

| Depth B [mm] | - | 25 – 70 | - |

- with eurohole or another type of hanger according to individual customer requirements,

- with a side cut - easy opening of the bag,

- with cap 45° or 90°,

- with a zipper closure,

- with seal narrow 4 mm or wide 8 mm.

- with a vent for venting

- with side fold

Bags for liquid products, sauces and liquid soaps

We offer standard closures located in the middle of the bag as well as on the edge at an angle of 45 degrees.

Information and offers regarding the bags; e-mail; papier@pakmar.com.pl; torebki@pakmar.com.pl